History

This is the History of Mills and Dams Along the Norwalk River

Arranged By Brent M. Colley. Histories of Mills and Dams coming from Wilbur F. Thompson articles written between 1915 and 1930, later made available by Irene Baldwin in 1965. Additional photos, maps and information to enhance the Thompson material were added in 2005.

The History of Mills and Dams Along the Norwalk River

The Old Stone Mill by Wilbur F. Thompson.

John Taylor of Wilton was the first to operate a mill in the location that would come to be known as the Old Stone Mill, and at one time- Perry's Glenburg Chemical Works. John Taylor's Mill was called Taylor's Woolen Mills or the Satinet Factory. He built a dam a short distance above the mill and a canal to convey the water to the mill (this canal is still visible from the train today). He also built the house by the mill and lived there many years.

View from what is now the Georgetown Lions Club Ballfield.

Henry Williams, who lived a short distance below the mill, had charge of the dyeing, carding and spinning department; his wife was one of the weavers. A man named Eli Glover also worked there. He afterward ran the mills known as Glover's Woolen Mill west of Sanford's Station in West Redding (corner of Topstone Rd and Route 7 where Cains Hill is. Cains ran a Fulling Mill). ohn Taylor was in business many years, and after he retired, a Welshman named Evans, from Derby, CT, continued the business. After this, Blackman Bros., from New Milford, ran it for a short time. Later Dr. N. Perry, of Ridgefield, bought it; and fitting it up for a grist mill and to grind spices, called it the Glenburg Chemical Works. Perry attempted to change the name of Georgetown to Glenburg, but did not succeed. His son, Samuel Perry, had charge of the mill for many years. The famous remedies so well known in the 1850's & 60's were made here - composition powders for colds, magnesia powders for indigestion, the No. 9, a pain killer, demulcent, compounds for coughs, and many others. Spices were ground and all kinds of extracts were made and sold. The country stores all kept the Perry remedies, spices and extracts. After the death of Samuel Perry, the formulas for the Perry remedies came into the possession of his brother-in-law, Eli Osborn, who made them for many years, at his home in Georgetown. The mill was sold to William J. Gilbert who leased it to different parties who ran it as a grist mill. Later the mill was owned by Samuel J. Miller…the roots of the G&B factory ran deep.

About Flax and Woolen Mills

Two of the most important products of the farms of long ago were wool and flax. On summer days flocks of sheep could be seen feeding on the hillsides and waving fields of blue-flowered flax could be seen on almost every farm. Flax was not harvested the same as grain or hay, but was pulled up by the roots and stacked. Later in the season it was put through a process of sweating or rotting to separate the fibre from the woody part of the stalk. It was then crackled to break the wood or straw of the flax. This was done by beating it with wooden mallets. After this, it was hetcheled or hackled; this was done by drawing the stalks of flax over sharp pointed iron teeth thickly set in a block of wood. This separated the fiber from the woody or straw portion of the flax. The fiber, after hetcheling, was called tow or lint; this was cleaned and spun into linen yarn or thread, and woven on the hand looms into different kinds of linen cloth, and then bleached. The wool was worked up in a different way. After being sheared from the sheep, it was washed and cleaned. Then it was carded into a light fleecy mass (like the cotton batting of today.) The hand cards were pieces of leather or thin wood thickly set with fine wire points which caught and separated the fiber of the wool. Sometimes the wool was bowed the same as hatters' fur was in the olden times. This was done with a large bow strung with catgut; pulling the string caused it to vibrate in the wool, separating it the same as in carding. After carding, the wool was formed into rolls, from which it was spun into woolen yarn or warp and then woven into woolen cloth of many kinds, and blankets. A cloth for dresses and skirts was woven, called linsey-woolsey. It had a linen warp and woolen filling; a heavier cloth made of the same materials was called fustian. After washing, the cloth was dyed, fulled. and finished.; oftentimes the warp and filling were dyed before weaving. For many years all this work was done by hand on the farms where the wool and flax were raised. Later little shops and mills were built along the stream where the wool and flax were prepared. for weaving and where the home-made cloth was fulled and finished.

Mills Along Old Mill Road in Georgetown by Wilbur F. Thompson & notes by Brent M. Colley.

From the early settlement of our state until about 1850, the people living in our rural communities were, to a great extent, independent of the outside world; the farms and little shops and mills producing almost everything used in the homes of their day. At one time there were approximately sixteen busy shops and mills along the banks of the Norwalk River from its source in Ridgefield to tidewater in Norwalk. Today all that remains are the bricks and stones of their foundations and dams. The information below (a large majority of which comes from Wilbur F. Thompson) explains their history and the individuals that worked them many years ago.

The first mill to be built in the early days was the Grist Mill, then the Saw Mill, Blacksmith Shop, Woolen Mill, Tannery and Cider Mill. Georgetown was no exception to the general rule, and along its streams and highways are found evidences of many little home industries that flourished, long years ago. It is probable that the first corn and grain raised in Georgetown was ground in the home-made mortars of wood or stone, with a pestle, or in the old Indian stone samp mortars which can be found in the rocks along the Norwalk River in many places. The first Grist Mills where the early settlers of Georgetown had their corn and rye ground were located outside of the village. One stood on the west bank of the Saugatuck River, near the foot of Nobb's Crook Hill. (This was about 1730). The miller's name was Jabez Burr. Many years later a wind grist mill was built in what was called Dumping Hole or Hill (now in Cannondale School District,) about two miles southeast of Georgetown. Another Grist Mill located at the intersection of Florida Hill and Old Redding Road, operated by Peter Burr and dating to 1737 was a likely source for the settlers as well.

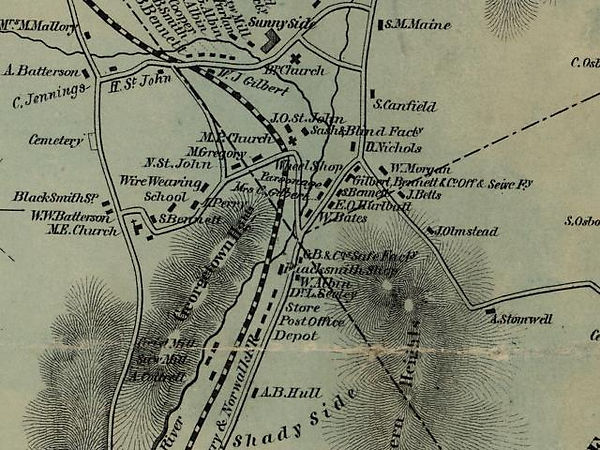

Clark Map of 1856 showing Saw Mill and Foundry (earlier this was the Grist Mill location mentioned). The location is a tad to the left of E.B. Sanford between the "E" and "D."

The first grist mill in what is now the village of Georgetown was probably built and run by George Abbott. If there was one before this, the name of the owner is not known. In 1764 George Abbott, formerly of Salem, Westchester Co., Province of New York, bought of Ebenezer Slawson, of Norwalk, a mill privilege on the Norwalk River for the purpose of erecting a grist mill. The mill was built and he commenced to grind corn and grain. There is also a tradition that John Belden had built a saw mill on or near the same site, and Abbott purchased that mill site from him as well. Located on the only road between Danbury and Norwalk it was a very profitable business; people from miles around brought their grain to be ground, or logs to be sawed up into lumber.

.jpg)

Clark 1856 Map showing Grist Mill, Saw Mill on the left

Abbott ran the mills for many years and his wife (known as "Aunt Lucy") kept a tavern or half-way house for the teamsters traveling the Danbury and Norwalk turnpike. A long list of owners followed Abbott at this location. The next owner of the mill was Stephen Perry. He rebuilt the dam and mill; and it became known as Perry's Mill. Later Joseph Goodsell the 1st. ran the mill. The next owner was Ephraim B. Godfrey and his son Wakeman Godfrey. Godfrey & Son ran the grist and saw mill for many years and did a large business. Glenburg Chemical Works would put Wakeman Godfrey out of business. Some time after, Edwin Gilbert bought the property, rebuilt the mill dam and mill, enlarging it, and fitting it up for other manufacturing; for a while, Betts & Northrop had a carpenter shop there as well. Blood's patent flour sifter and other wire goods were made there at that time. Later the Gilbert & Bennett Co. gained ownership and changed it into a wire mill, the third floor of this mill was set up and ran the second machine in this country for making wire netting and fencing in 1869 and '70. In 1865 Gilbert & Bennett & Co. had installed the first power machinery for making wire poultry netting. It was used for that line of work until it burned down around the early 1900's. G&B converted this entire area into it's "Lower Factory" wire mills. The "Lower Factories" included several manufacturing buildings, a wire drawing plant and a dam large enough to create what was known as the Lower Factory Pond.

.jpg)

Lower Factory Pond looking back toward Old Mill Road

The Lower Factories were the last mills in this location serving Gilbert & Bennett well in their life span. G&B would later focus their attention on the factories we know today between North Main Street and Portland Avenue. Back then these factories were referred to as their Upper Factories. Improvements in the railroad, particularly the spur line that was run into the Upper Factories in 1874 led to the expansion of and focus on this location. The Lower Factories were all lost to fire over time.